How can a tech giant 'build' a smartphone chip without its own foundry?

Money, knowledge, and engineering can't replace manufacturing. Or can it?

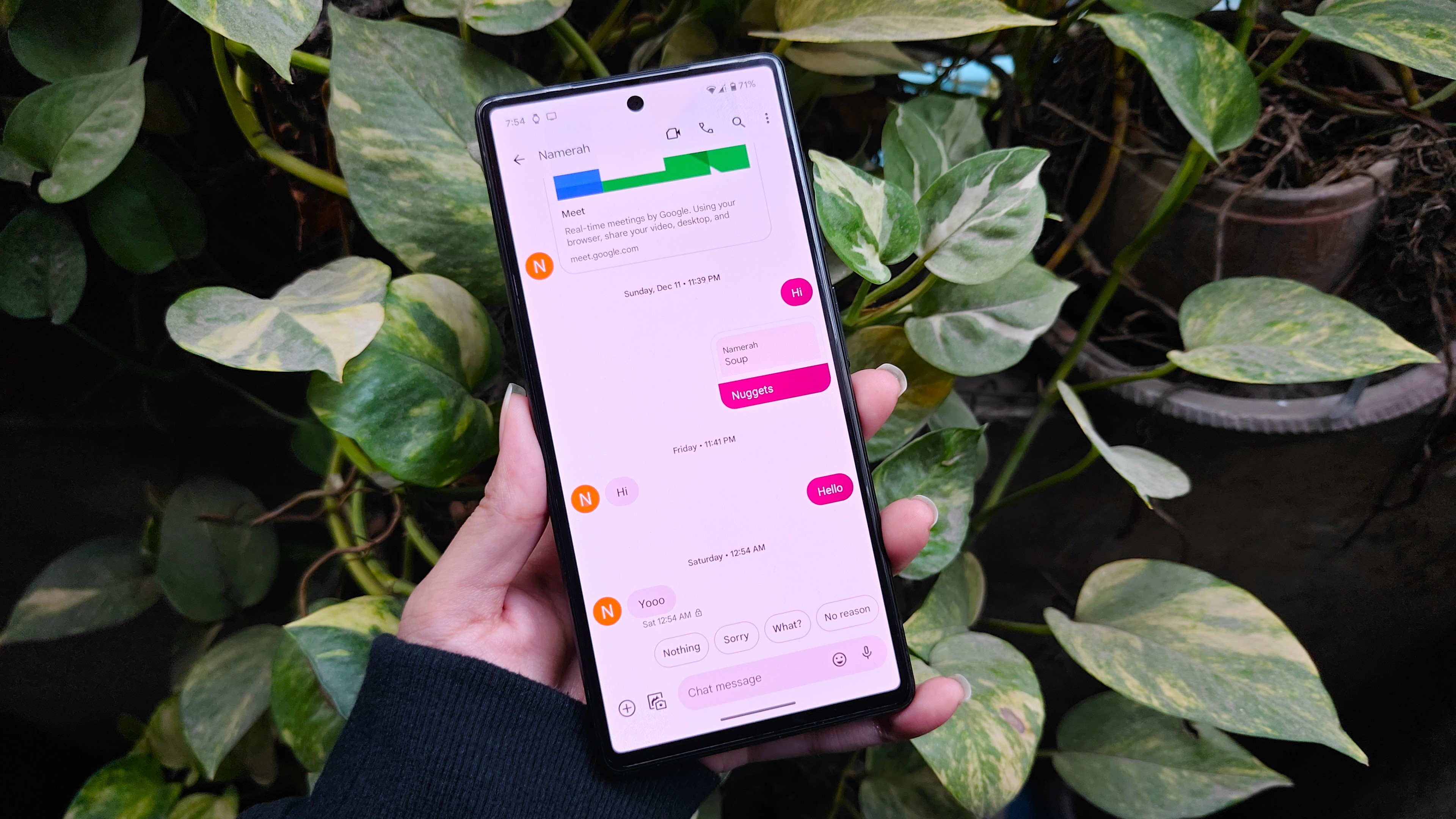

The modern smartphone is a marvel of miniaturization, packing the power of a desktop computer into a device that fits in your hand. At the heart of this revolution lies the System on a Chip (SoC), a single integrated circuit that houses the CPU, GPU, modem, and a host of other specialized processors.

While companies like Apple and Google are known for "building" custom smartphone chips, they don't actually manufacture them. Samsung also designs chips and can build them, albeit in a different division of the company. Qualcomm has changed the industry forever by designing things nobody could ever build without them, and the company lets others build the actual products.

So, how do these tech giants design and bring these powerful components to life? The answer lies in a complex interplay of design expertise, intellectual property, and a specialized manufacturing ecosystem.

Turning an idea into a blueprint

The journey begins with the design phase, where teams of engineers, architects, and researchers conceptualize the chip's architecture. This involves defining the chip's functionalities, performance targets, and power efficiency goals.

For Apple, this means optimizing for iOS and its specific applications; for Google, it's about tailoring the chip to Android and its burgeoning AI capabilities. Samsung and Qualcomm need to build chips that anyone can use. It's not easy.

The core of the chip's design is its architecture. This dictates the arrangement of the various processing units and how they interact. Apple, for instance, invests heavily in its custom CPU and GPU designs, aiming for superior performance per watt. Google, with its Tensor chips, focuses on integrating specialized AI accelerators for on-device machine learning. Qualcomm strikes a balance between performance in all areas and connectivity options.

Each company knows what it needs better than anyone else does.

Be an expert in 5 minutes

Get the latest news from Android Central, your trusted companion in the world of Android

Once done on paper, engineers need to describe and build out the chip's logic. Hardware Description Languages (HDL) like Verilog or VHDL are used to "program" every behavior of the chip's circuits: every transistor, logic gate, and even the connections between them all.

Once someone is satisfied that this is going to work, the testing begins before anything is ever built. Software is used to simulate various behaviors, looking for bottlenecks in performance and potential errors and determining what other IP could be licensed to make a chip even better. Nothing is built in a vacuum, and no one company can do it all; the best products are a happy collaboration.

From there, the process is physically laid out by crazy smart people with backgrounds in electronics, physics, and manufacturing. Finally, parts can be built.

Apple or Qualcomm don't build their own chips. Neither does Google, and even the divisions at Samsung designing new products aren't usually the same ones creating them. For that, you need a semiconductor foundry. TSMC is one of the biggest, but there are others — including Samsung's own foundry.

The company that designed the chip works very closely with the foundry. There's a lot of back and forth to optimize the design for better performance and ease of manufacturing, and the final specifications are drawn out before the first chip rolls off the line.

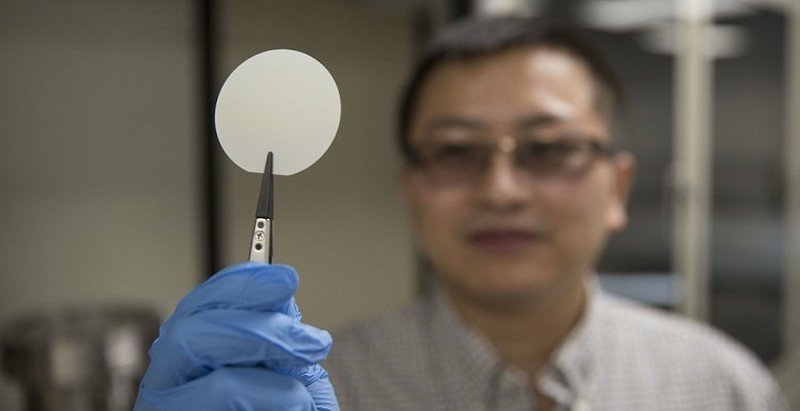

The process of building a semiconductor is wild. Using complex masks and stencils, a chip is built layer by layer in rooms where not even a spec of dust is allowed. It's a total sci-fi vibe for a sci-fi product. The results are continually tested so the "good" chips make it to the customer who ordered them, then into your hands.

The fabless model has plenty of advantages

It's easy to think of fabless semiconductor design as sort of like outsourcing, but it's a lot more than just a cost-saving initiative.

It allows a company like Apple or Qualcomm, who are well known for building excellent smartphone chips, to focus on the design and licensing of outside IP to build a product that meets consumer's exact needs.

Instead of trying to build and maintain advanced state-of-the-art facilities, they can partner with a company that has both the means and the experience to do it right. This makes adapting to an ever-changing market much easier.

Expertise in chip design, combined with strategic partnerships with leading manufacturers, allows them to create some of the most powerful and efficient smartphone chips on the market. This intricate ecosystem, where design expertise meets manufacturing prowess, is what drives the relentless innovation in the world of mobile technology.

Jerry is an amateur woodworker and struggling shade tree mechanic. There's nothing he can't take apart, but many things he can't reassemble. You'll find him writing and speaking his loud opinion on Android Central and occasionally on Threads.

You must confirm your public display name before commenting

Please logout and then login again, you will then be prompted to enter your display name.