Here's how much it costs Samsung to make the Galaxy S23 Ultra

Samsung's profits may be sliding, but it's clearly making bank with its flagships.

Samsung just recorded its lowest profits in 14 years on the back of cratering demand for memory products. Samsung Memory falls under the brand's semiconductor unit, and over the course of the last decade, this has been the biggest revenue driver for the South Korean giant. But in the latest quarter, the business recorded a loss of $3.4 billion on the back of unsold inventory and decreased demand, taking a huge chunk out of Samsung's profit margins.

Samsung is predicting a turnaround for its memory business in the latter half of the year, but until then, it's turning to its phone unit to drum up some much-needed profits. There's good news on that front, as a recent bill-of-materials analysis of the Galaxy S23 Ultra by the folks at Counterpoint Research suggests Samsung is making a decent profit off of its flagships.

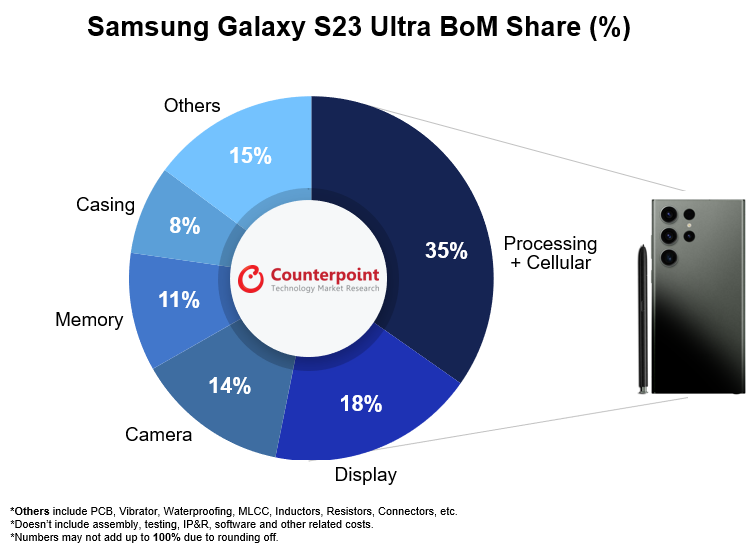

Counterpoint notes that it takes Samsung $469 to manufacture the Galaxy S23 Ultra; as a reminder, the phone retails for $1,199. Basically, the bill of materials comes out to just under 40% of the retail value of the Galaxy S23 Ultra, so even with Samsung offering heavy incentives to customers to switch, it manages to eke out a tidy profit with the device.

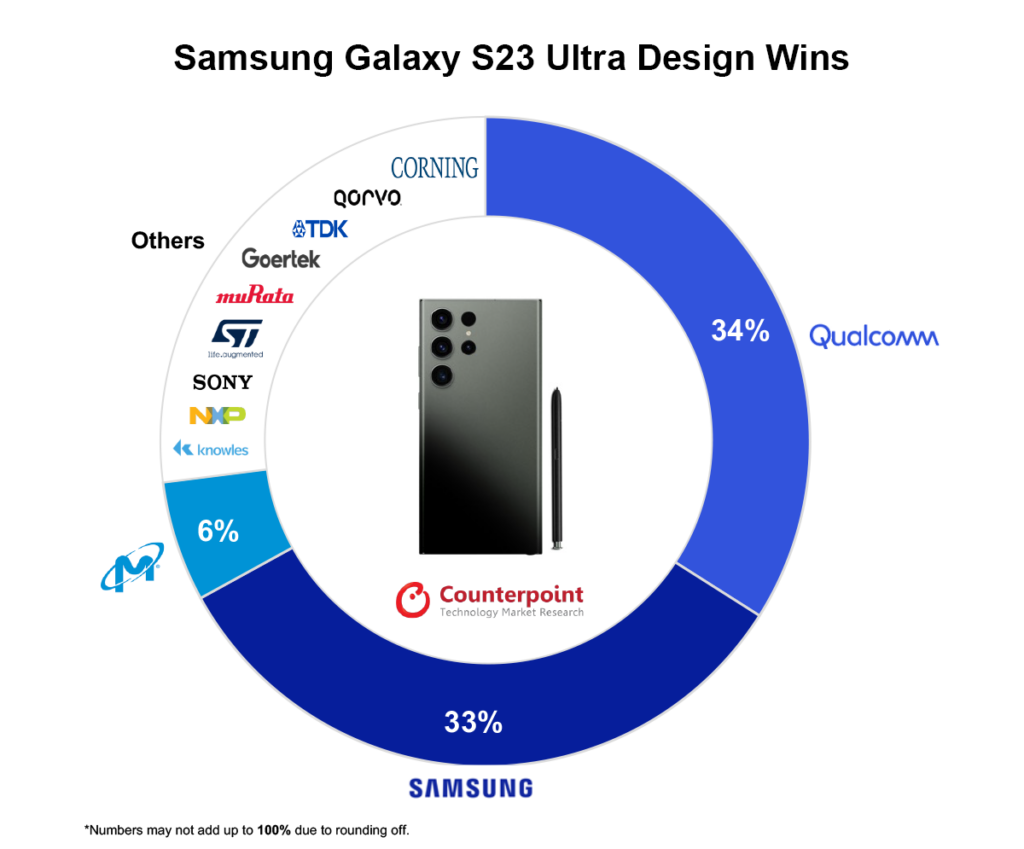

An interesting pointer in Counterpoint's analysis is that Qualcomm accounts for 34% (or $159) of the overall manufacturing cost of the S23 Ultra, and this includes the cost of the Snapdragon 8 Gen 2 for Galaxy, ultrasonic fingerprint sensor, Wi-Fi, Bluetooth, GPS, and Sub-6 5G cellular antennae, AptX audio codecs, and various power management ICs.

The second-largest beneficiary is Samsung's other business units. Samsung is unique in the industry in that its various businesses manufacture displays, memory and storage modules, and camera hardware.

The Galaxy S23 Ultra uses a 6.8-inch 120Hz AMOLED panel made by Samsung Display, and 256GB/512GB/1TB storage modules as well as a 200MP camera sensor manufactured at Samsung Semiconductor. Samsung also uses Sony's imaging hardware for the auxiliary cameras of the S23 Ultra, but all the parts produced by various Samsung subsidiaries come out to 33% of the total manufacturing cost of the device.

Of course, a bill-of-materials analysis doesn't take into account money put toward research, marketing, and other initiatives that are needed to get a product out, but it provides an insight into how much high-end gadgets cost.

Get the latest news from Android Central, your trusted companion in the world of Android

At the end of the day, the Galaxy S23 Ultra is a terrific all-round device, and whether you traded in your old device and got a good deal or paid full price, you're getting one of the best Android phones of 2023.

With a gorgeous design and some of the best hardware you'll find on a phone, the Galaxy S23 Ultra nails the basics. Throw in a terrific camera and long-term software updates, and you have a stellar all-round package.

Harish Jonnalagadda is Android Central's Senior Editor overseeing mobile coverage. In his current role, he leads the site's coverage of Chinese phone brands, networking products, and AV gear. He has been testing phones for over a decade, and has extensive experience in mobile hardware and the global semiconductor industry. Contact him on Twitter at @chunkynerd.