Adventures in 3D Printing — dealing with failure

For the last week, I have been fortunate enough to mess around with the Ultimaker 2 3D Printer. Having a 3D Printer 10 feet from your desk is an incredible experience, and the list of things I want to print is growing way faster than the list of completed projects. Complicated prints with this device can get upwards of 30 hours pretty quickly, but the end result is so worth it. I've made accessories for phones that I am really happy with, organization tools for the house that look nice, and little things for my kids to play with. I've been excited about 3D Printers for a while, but the feeling of satisfaction as the build plate sinks to the base of the structure so you can grab the finished print was something I wasn't really expecting.

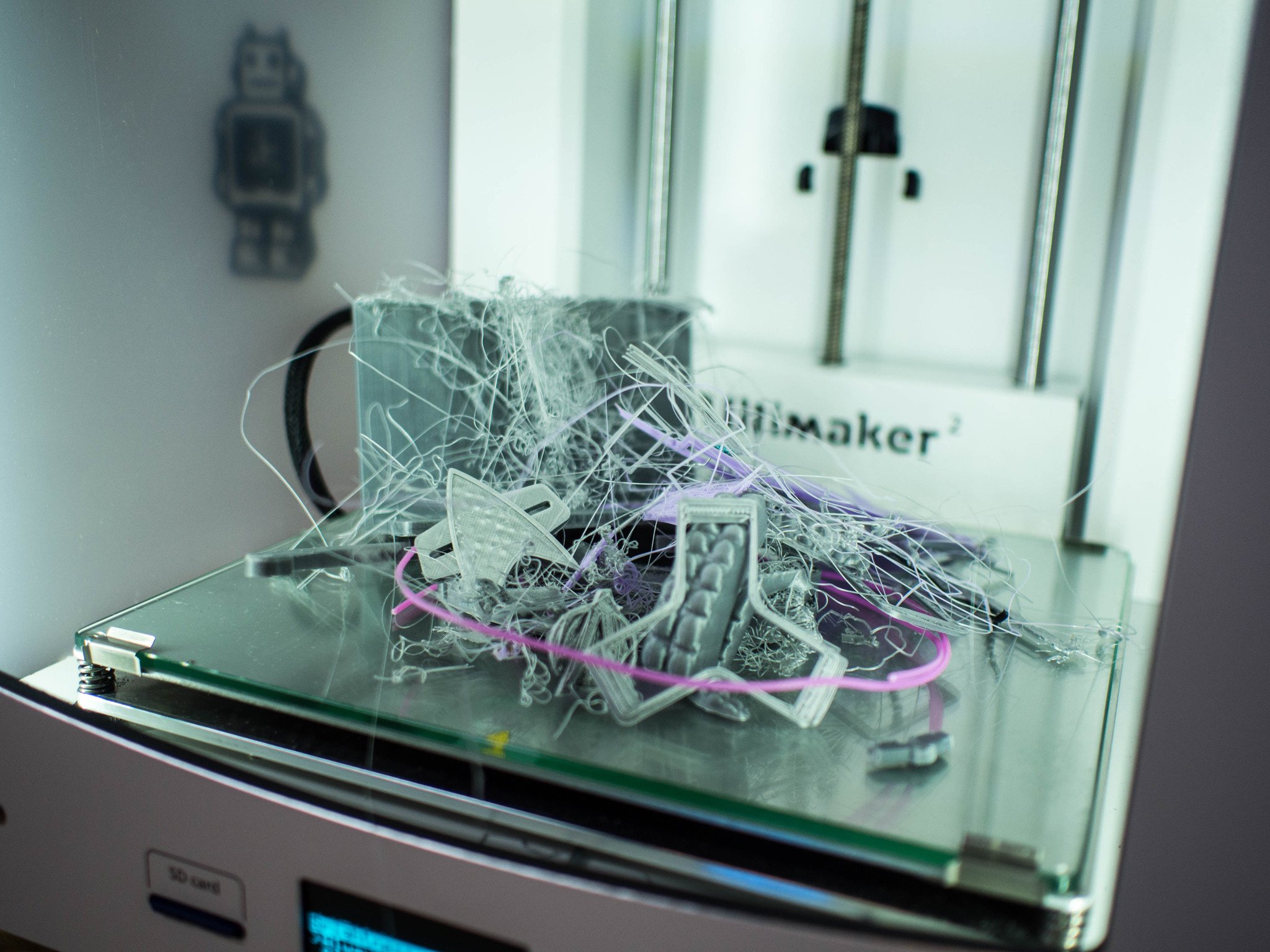

There's another feeling I wasn't expecting in this 3D Printing adventure, and that's the whole-body cringe when I realize something has gone horribly wrong and my print has failed. I've had quite a few of those already, so it seemed right to share those experience as well.

It doesn't take much to guess that your print is going to fail. 3D Printers are not smart machines, it gets a set of instructions and acts on those instructions until the job is done. Like old paper printers, there are no sensors to make sure things are going well. No 3D version of "paper is jammed" or "ink is running low". You're on your own, and unless you are intimately familiar with how the machine you are giving instructions to actually works it is easy to get lost. Even after using 3D Printers for quite a while, veterans in this ecosystem admit to a 70% success rate being a very good thing for users of any skill level.

What do those failures look like? Lets take a look.

These three are attempts to make a speaker dock for the OnePlus One. The purple attempts are with ABS fibers, which I learned the hard way require a consistent temperature inside the machine to avoid the base of your structure warping off the buildplate. Since the Ultimaker 2 isn't a closed system out of the box, I switched to PLA and tried again. That grey print in the middle failed when the filament got caught on itself on the spool, because it wasn't wound correctly before it was shipped to me. There was no filament getting to the printer, and the machine had no idea something was wrong. It just kept trying to print.

This was supposed to be a nice smartphone stand that looked like a tentacle, but at some point in the print process the left part of the print separated from the build plate and got smashed together with the rest of the design. The printer just kept going and finished printing the other tentacle, but obviously this isn't going to be holding anything.

I found this simple toothbrush holder on Thingiverse and thought it would look nice in my bathroom, but didn't think about how the machine actually prints things before sending the file to the printer. See, 3D printers operate in single line slices, and since there were no support structures for the top the machine printed lines of plastic that connected to nothing, leaving this mess as a result. Rotating the print so it looked like a "U" in the software fixed this problem, but not after I wasted 10 hours printing this monstrosity.

Be an expert in 5 minutes

Get the latest news from Android Central, your trusted companion in the world of Android

Every once in a while, the build plate on this printer needs to be re-calibrated. The printer works best when it is 1mm from the build plate, and if that doesn't happen you get prints like this. The lines don't connect correctly, and while it's technically a finished print everything looks sloppy. This is a quick thing to fix, but after re-calibrating this build plate a dozen times in the week I've had this printer I am all for auto-leveling being a standard feature in these devices.

I have no idea what happened here. This is my first attempt at printing a pocketwatch-style clip for the Moto 360, and should have been a fairly simple thing to print. I've been told by veteran 3D Printers that a lot of current-generation devices have trouble with little things. A second print of this design with a few tweaks turned out significantly better, but it's still not totally clear what caused this mess.

This is just a sampling of the failures I've seen so far, the stuff that actually looks like something and isn't just a blob of melted plastic or a series of tiny plastic wires. It's clear that the learning curve for 3D Printing in general is still very high, but in the space of a week I've managed to isolate a lot of problems and increase my success rate dramatically. A big part of that is support from the dozens of forums on the topic, where so many problems have already happened and been resolved before.

It'll be very interesting to see how manufacturers attempt to decrease the number of potential failure points in an attempt to make the technology more user friendly, and how skilled users will react to the changes that will undoubtedly happen to make those changes possible. Until that happens, my failure pile is likely to continue growing in new and bizarre ways.